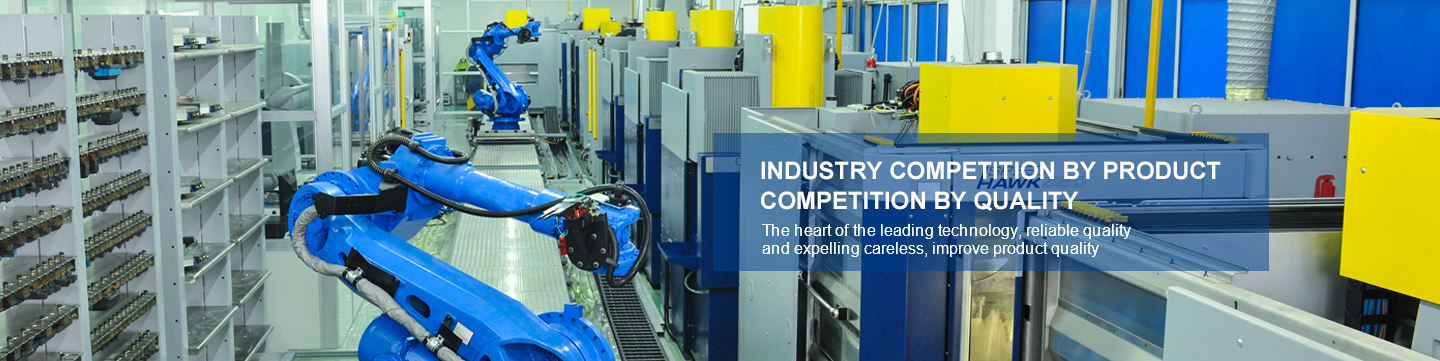

Car milling integrated flexible production line combined with milling process. This production line adopts the ship 20 kg of six degrees of freedom, independent research and development of intelligent industrial robots and control system, can realize the presence of unmanned automatic processing. Production line is mainly composed of a machining center, a CNC lathe and a six axis robot, with guide rail, rack, loading and unloading station, cleaning stations, fences and other auxiliary parts, and through the unit management system unified control.

This production line has realized the different system of processing equipment and the organic combination of DE ji robot, can ensure that in the presence of no one realize high efficient automatic production. At the same time, the system is equipped with order management software, can carry on the configuration, convenient for processing program to arrange the production plan. The system will automatically according to the processing situation processing task scheduling and distribution, in order to achieve the maximization of efficiency.

Production line control system, is the core of realizing automation production. With adding production tasks, the production data management, material warehouse management, equipment management, production scheduling, production safety management, and other functions. For automatic production line control system, as the brain controls the whole production line operation.

Processing center, processing center can use FAGOR, FANUC system of machining center, etc. According to the practical production requirements.

Wheel robot: a great JLRB20 JLRB50 or other type of six degrees of freedom, industrial robot, can undertake choosing according to the practical production requirements.

Material warehouse: to hold for processing and processing of materials, adopts the principle of book posture stereoscopic warehouse, warehouse location, size according to the actual need to carry on the design.

Convenient loading and unloading station: operator, loading and unloading material can be installed according to the actual demand to choose or not.

Online cleaning equipment, testing equipment: according to the actual demand for installation.